Introduction to Our Inspection Services

At Design Solutions Machining, our Inspection Services ensure every part meets exact specifications before it reaches production or delivery. Whether you’re validating prototypes, checking tolerances, or conducting full capability studies, we use advanced tools and statistical methods to verify accuracy, consistency, and compliance.

Our team combines CAD integrated inspection planning with decades of hands on experience to minimize errors, reduce rework, and uphold the highest standards of quality. From first article inspection to ongoing process monitoring, we collaborate closely with you to ensure every measurement reflects real world performance.

Inspection Capabilities

Dimensional Inspection with CAD Integration – We measure parts against CAD models using precision tools and digital overlays.

Statistical Process Control (SPC) – We monitor trends and variation using control charts and statistical methods.

Documentation & Reporting – We provide full inspection reports, traceability logs, and compliance records for audits and quality reviews.

What Our Inspection Services Include

First Article Inspection (FAI)

We verify initial production runs against design specs ensuring parts meet dimensional and functional requirements.

In Process & Final Inspection

We monitor parts during and after production to catch

deviations early and confirm final quality.

Measurement System Analysis (MSA)

We assess the accuracy, repeatability, and reliability of your measurement tools and processes.

Visual & Attribute Inspection

We inspect surface finish, defects, and visual criteria using binomial or Poisson capability charts.

Benefits of Our Inspection Services

Reduced Defects & Rework

Catch issues early and minimize costly production errors.

Improved Process Stability

Use statistical insights to monitor and improve manufacturing consistency.

Compliance with Industry Standards

Meet ISO, ASME, and customer specific inspection requirements with documented verification.

Enhanced Customer Satisfaction

Deliver parts that meet expectations every time.

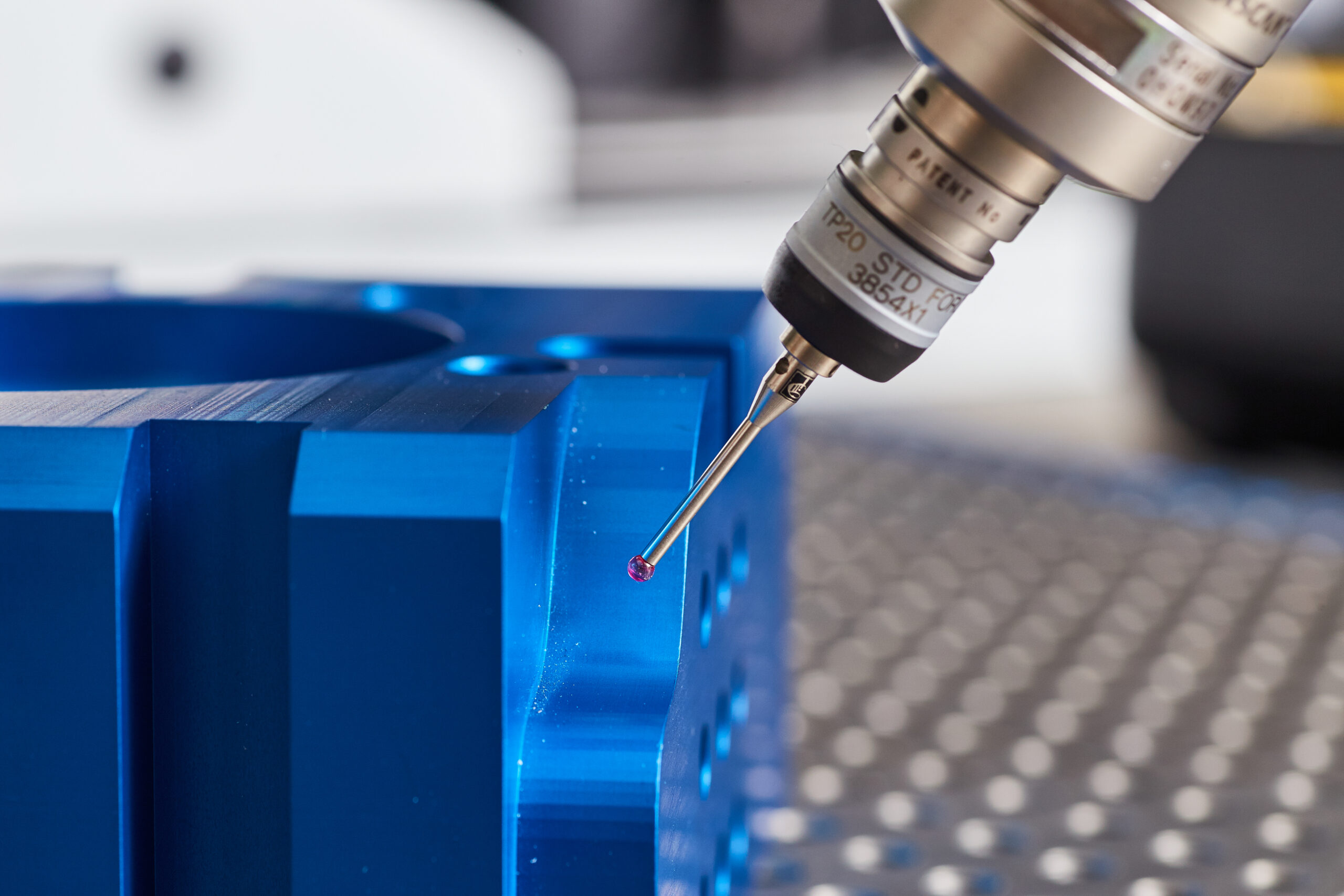

Inspection Equipment

RAM Optical OMIS III

Optical measurement system for high-precision, non-contact dimensional inspection.

Hexagon Global Advantage 575 Bridge CMM (with probe scanning)

High-accuracy coordinate measuring machine for complex geometries and tight-tolerance verification.

Keyence XM-2200 / XT-2200 Handheld Probe CMM

Portable CMM system for fast, flexible, shop-floor measurement.